Advancing Cancer Therapies: BioAssemblyBot's Precision in Nanoparticle Fabrication

- Advanced Solutions

- Sep 18, 2024

- 2 min read

Updated: Dec 17, 2025

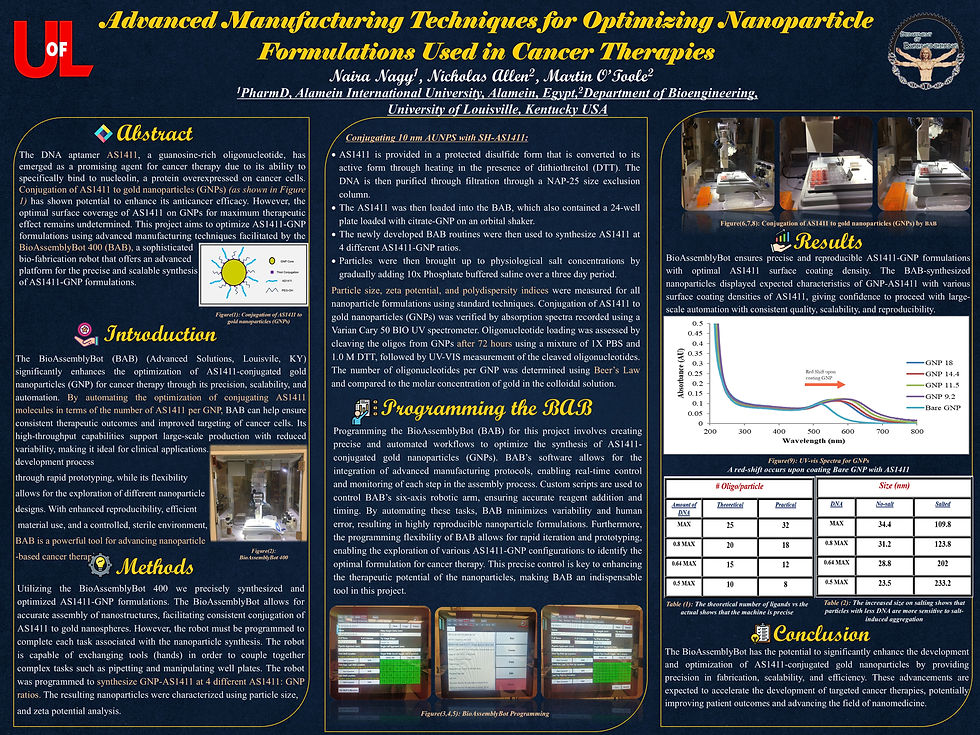

Nanotechnology is reshaping cancer treatment, offering new avenues for targeted therapies that promise greater efficacy with fewer side effects. Among these innovations, DNA aptamers like AS1411 conjugated to gold nanoparticles (GNPs) have emerged as a particularly promising approach. AS1411, a guanosine-rich oligonucleotide, specifically binds to nucleolin—a protein overexpressed on the surface of cancer cells—making it an ideal agent for tumor targeting. However, optimizing the surface coverage of AS1411 on GNPs to maximize therapeutic effectiveness remains a significant challenge. This is where the BioAssemblyBot (BAB) 400 steps in, revolutionizing nanoparticle fabrication with unparalleled precision and automation.

The Power of Precision and Automation with BioAssemblyBot

Developed by Advanced Solutions, the BioAssemblyBot 400 is a state-of-the-art biofabrication robot transforming nanoparticle synthesis for cancer therapies. Equipped with a six-axis robotic arm, BAB automates the intricate process of conjugating AS1411 molecules to gold nanoparticles. This automation ensures exceptional precision, scalability, and consistency—critical factors for clinical applications. The robot adeptly handles complex tasks including precisely controlled reagent addition and well-plate manipulation, resulting in AS1411-GNP combinations with remarkable accuracy.

BAB significantly reduces variability and potential errors, leading to highly reproducible results. This level of precision is essential when fine-tuning the surface coating density of AS1411 on GNPs, directly impacting the nanoparticles' ability to effectively target cancer cells.

Optimizing AS1411-GNP Formulations for Enhanced Targeting

Optimizing AS1411-GNP formulations involves meticulous adjustment of the ratio between AS1411 molecules and gold nanoparticles. Utilizing BAB's capabilities, researchers can systematically test various AS1411-to-GNP ratios. BAB carefully combines reagents through the controlled addition to a phosphate-buffered saline bath to produce uniform, stable particle suspensions. Measured particle sizes, zeta potentials, and polydispersity indices qualify successful conjugation and specified nanoparticle characteristics.

One of BAB's standout features is its programmable flexibility, allowing rapid prototyping and exploration of different nanoparticle configurations. This agility accelerates development, enabling researchers to swiftly identify the most effective formulations for clinical applications.

Innovating Cancer Therapy Through Nanotechnology

The precision and reproducibility offered by the BioAssemblyBot are invaluable in enhancing nanoparticle fabrication for cancer therapy. By optimizing the surface coating density of AS1411 on GNPs, researchers can significantly improve targeting specificity toward cancer cells, potentially leading to better patient outcomes with fewer side effects. Moreover, BAB's scalable manufacturing process ensures that once an optimal formulation is identified, it can be produced in large quantities without compromising quality—a critical factor for advancing treatments from the lab to clinical trials.

Conclusion

The BioAssemblyBot 400 stands at the forefront of nanomedicine innovation, offering a transformative approach to synthesizing AS1411-conjugated gold nanoparticles. Its ability to automate and optimize complex fabrication processes not only streamlines research but also paves the way for more effective and targeted cancer therapies. As the medical community continues to explore the vast potential of nanotechnology, tools like BAB will be instrumental in translating groundbreaking research into real-world clinical solutions.

Source:

Nagy, N., Allen, N., & O'Toole, M. (2024). Advanced manufacturing techniques for optimizing nanoparticle formulations used in cancer therapies. Poster presented at Research Louisville, Louisville, Kentucky.

Comments