More than a bioprinter, much more.

Unlike traditional bioprinters, BioAssemblyBot 400 manipulates tissue assays over time, providing valuable information to users on the state of their biology. BAB400 can nurture and analyze biology throughout your entire workflow.

An adaptive, machine learning, biofabrication powerhouse.

From automated calibration to failure correction, BioAssemblyBot 400 uses machine vision and artificial intelligence to keep your biology happy, getting better with each print.

Expandable and designed for modern biology and drug discovery labs.

Produce living tissues, organoids, and spheroids more consistently than ever before. Then analyze them without ever touching the well plate. BAB400 integrates seamlessly with lab equipment, including confocal microscopes like Cytiva's IN Cell Analyzer and Molecular Devices' ImageXpress, with more integrations coming soon.

Develop new drug targets.

Create realistic 3D tissue models to use in drug discovery. Test drug toxicity on 3D models that are representative of native human tissues.

Make organoids with BAB400.

Quickly and easily explore viable prototype ideas. Produce quality preliminary data without delays allowing you to iterate designs and solutions.

Be the future of medicine.

Develop novel surgical techniques that incorporates robotics and 3D bioprinting. Improve patient care with better, faster, and innovative methods.

Share nicely.

Be a good steward of shared laboratory space by employing an easy-to-use, easy-to-learn biofabrication system. Attract more users (and grants) to your facility with the world's only six-axis bioprinting platform.

6-axis

Robotic Arm

8

BioAssemblyTools in a single run

Attached touch screen controls

HEPA Filtration

Clean Room

Ready

Accessory Ready

Works with BioStorageBot & imagers

Build Volume

12 in (l) x 10 in (w) x 7 in (h)

30.5 cm (l) x 25.4 cm (w) x 17.8 cm (h)

3D Printing Technology

Pneumatic or Mechanical Dispense

BioAssemblyBot Hands Compatibility

Works with all tools

HEPA Specifications

99.97% of particles to 0.3 µ

Air Flow Requirements

100psi 1cfm

Base

Optional Table

Temperature Controls

Stage: 10 to 60 C

3D Syringe | Hot: Up to 150 C

3D Syringe | Cold: Down to 0 C

Connections

Power Supply Input

RJ45 CAT-5

Pneumatic Air Fitting

Electrical Panel

Internal

Electrical Requirements

Bioprinter:

208-220 50/60 Hz Single Phase @ 20 Amp Isolated Receptacle (NEMA 6-20R)

-

Dimensions & Weight

Bioprinter:

36.8 in (w) x 29.5 in (d) x 52.9 in (h)

93.5 cm (w) x 75.0 cm (d) x 134.3 cm (h)

600 lbs

272 kg

BAB400 Standard Table:

36.8 in (w) x 29.5 in (d) x 81.75 in (h)

93.5 cm (w) x 75.0 cm (d) x 81.75 in (h)

Ready to meet BAB400?

Book a demo or get a quote, she can't wait to meet you:

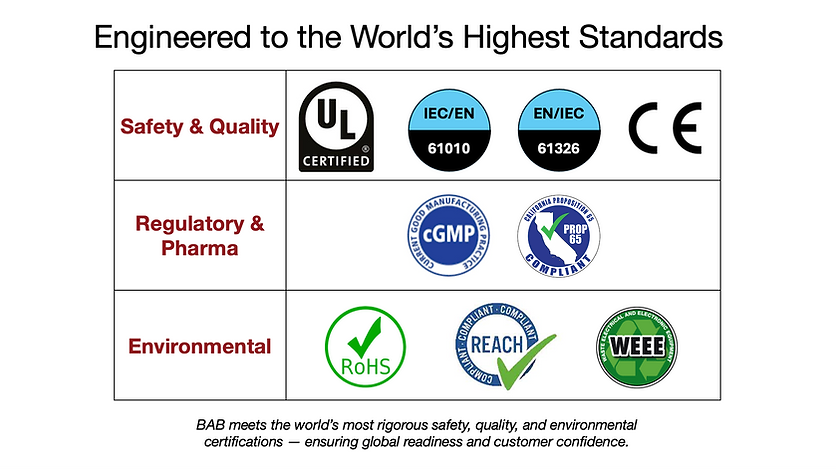

The BioAssemblyBot 400 is certified by UL in accordance with applicable safety requirements. The BioAssemblyBot 400 is certified by UL in accordance with applicable energy efficiency requirements.

The Advanced Solutions Louisville, KY facility has been audited by UL Registrar LLC and meets GMP requirements listed in RCP, NBCP, or Pharmaceutical Certification Schemes which is uniquely accredited by the American National Standard Institute (ANSI) developed in accordance with applicable sections of the FDA’s code of federal regulations.