The future of curative healthcare.

BioAssemblyBot 500 provides the next level of environmental control over the biofabrication process. The six-axis robotic arm and the collection of tools make BAB500 a unique offering for tissue engineering. With it being housed in a biosafety cabinet to ensure a sterile environment, life scientists will have further control over all parameters in their assays.

Building 3D biology for humans.

BioAssemblyBot 500 is the only six-axis biofabrication device with an integrated Class II, Type-A biosafety cabinet. BAB500 can be easily taught to translate your biology recipe into clinical solutions.

Be empowered to the solve tough scientific challenges.

Disrupt the status quo by setting a new scientific standard and change the paradigm in experimental capabilities and approaches.

Become the catalyst of good.

Discover new methods, applications, and purposes for existing medications and treatment methods.

Discover Drug Efficacy, Faster.

Create better, smarter disease models with a higher fidelity to the native tissue assay, producing fewer false positives.

Publish more.

Produce more peer-reviewed publications and support faculty research endeavors. Expand your ability to win grant dollars.

BioAssemblyBot 500 Key Features & Specifications:

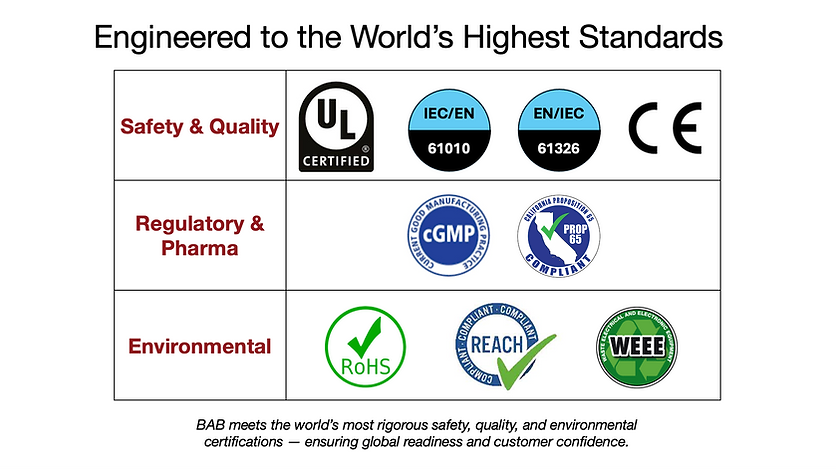

UL cGMP Certified

HEPA Filtration System

Class II, Type-A Biosafety Cabinet

6-Axis Robotic Arm

Touch Screen Control Panel

Temperature Controlled Print Stage

Adaptive Tip Detection

Use up to 10 BioAssemblyBot Hands

Required electrical cabinet not shown.

6-axis

Robotic Arm

10

BioAssemblyTools in a single run

Attached touch screen controls

HEPA Filtration

Clean Room

Ready

Biosafety Cabinet

Integrated

Build Volume

12 in (l) x 10 in (w) x 7 in (h)

30.5 cm (l) x 25.4 cm (w) x 17.8 cm (h)

3D Printing Technology

Pneumatic or Mechanical Dispense

BioAssemblyBot Hands Compatibility

Works with all tools

HEPA Specifications

99.97% of particles to 0.3 µ

Biosafety Cabinet Compatibility

Integrated Class-II, Type-A

Air Flow Requirements

100psi 1cfm

Base

Powered lift base

Temperature Controls

Stage: 10 to 60 C

3D Syringe | Hot: Up to 150 C

3D Syringe | Cold: Down to 0 C

Connections

Power Supply Input

RJ45 CAT-5

Pneumatic Air Fitting

Electrical Panel

External (w/ under device cubby)

Overall Requirements:

208-220V 50/60 Hz Single Phase @ 20 Amp Standalone, Isolated Circuit with 2x NEMA 6-20R outlets

Power for Biosafety Cabinet:

208-220V 50/60 Hz Single Phase @ 7 Amp Isolated Receptacle (1x NEMA 6-20R)

(The BSC is labeled with a 10 Amp rating at 230VAC)

Power for External Electrical Panel:

208-220V 50/60 Hz Single Phase @ 12.76 Amp Isolated Receptacle (1x NEMA 6-20R)

NOTE: A standalone circuit is required and cannot be shared with other devices.

Electrical Requirements

Dimensions & Weight

Bioprinter:

65.125 in (w) x 33.25 in (d) x 75.6875 (h)

165.42 cm (w) x 84.46 cm (d) x 192.25 cm (h)

1200 lbs

544.31 kg

External Electrical Panel:

24 in (w) x 29 in (d) x 23 in (h)

60.96 cm (w) x 73.66 cm (d) x 58.42 cm (h)

Ready to meet BAB500?

Book a demo or get a quote, she can't wait to meet you:

The Advanced Solutions Louisville, KY facility has been audited by UL Registrar LLC and meets GMP requirements listed in RCP, NBCP, or Pharmaceutical Certification Schemes which is uniquely accredited by the American National Standard Institute (ANSI) developed in accordance with applicable sections of the FDA’s code of federal regulations.