105 items found for ""

- Revolutionizing Life Sciences: The Power of Single Cell Dispensing

In the ever-evolving landscape of life sciences research, advancements in single cell measurement and assessment technologies are propelling us into a new era of discovery. From gene editing to antibody development, the precise manipulation and dispensing of single cells play a pivotal role in unlocking the potential of groundbreaking solutions. At Advanced Solutions Life Sciences, we're at the forefront of this revolution, introducing the BioAssemblyBot® Hand for Single Cell Dispensing — a game-changing innovation designed to streamline workflows and accelerate research outcomes. The Need for Single Cell Solutions: In today's research landscape, applications spanning gene editing, single cell genomics, antibody development, clonal expansion, and cell line development demand precise dispensing of single cells into well-plates or custom containers. However, challenges abound, from ensuring clonality to rapidly yet gently dispensing cells and increasing workflow throughput. The need for efficient and reliable single cell dispensing solutions has never been more pressing. Introducing the BioAssemblyBot® Hand | SCD: Enter the BioAssemblyBot® Hand | SCD — a cutting-edge solution born from our commitment to empowering researchers with innovative technology. Built upon the versatile BAB platform, the BAB Hand | SCD enables researchers to autonomously dispense single cells into a variety of plates and containers, seamlessly integrating this activity into larger, autonomous workflows. With real-time reporting capabilities through BAB's BioApps™ platform, researchers can track plating efficiencies, impedance measurements, operation timings, and imaging results with ease. Powered by Cutting-Edge Technology: The BAB Hand | SCD leverages impedance measurements and monitoring to precisely dispense single cells from suspensions into multi-well plates and containers. Powered by BAB's multi-axis arm, which mimics the capabilities of the human arm, our solution ensures efficient dispensing while seamlessly passing pneumatics, power, and data. With the intuitive software interface of BioApps™, researchers can translate protocols into automation commands, enabling real-time reporting and analysis. Results and Validation: Our meticulous preparations and validation processes have yielded impressive results. We've achieved high efficiency and reliability in dispensing microspheres and cells, as evidenced by our comprehensive reports and data analysis. By culturing dispensed CHO cells for subsequent colony formation and outgrowth evaluation, we've validated the effectiveness of our solution in facilitating clonal expansion and cell line development. The BAB Hand | SCD is not just a tool; it's a catalyst for impactful research outcomes. Join the Revolution: Experience the power of Single Cell Dispensing with Advanced Solutions Life Sciences. Our innovative solutions, coupled with our commitment to excellence, empower researchers to push the boundaries of scientific knowledge and drive impactful discoveries. Join us in revolutionizing life sciences research and unlocking new possibilities for the future. Download Full Application Note:

- Exploring Epson's Role in ASLS's Biofabrication Breakthrough: A Case Study Highlight

Advanced Solutions Life Sciences (ASLS) and Epson Robots have revolutionized biotechnology with the BioAssemblyBot (BAB), a platform that leverages Epson's advanced robotics for precise Biofabrication, such as 3D printing human tissues and organs. This collaboration highlights ASLS's innovative approach to automating complex biological manufacturing tasks, pushing the boundaries of what's possible in life sciences. For more details on this groundbreaking project, visit the Epson case study

- Tutorial: Automating Organoid Models and Assay Workflows

FOR IMMEDIATE RELEASE Advanced Solutions Chief Scientist, Dr. James Hoying, to Present Tutorial on Automated Workflow for Tissue Organoid Modeling in Collaboration with Molecular Devices at SLAS 2023 San Diego, CA, February, 24, 2023 - Advanced Solutions, a leader in bioprinting technology, and Molecular Devices, a leading provider of high-performance bioanalytical measurement solutions, are pleased to announce that they will be co-sponsoring a tutorial on the automated workflow for tissue organoid modeling at the SLAS 2023 Conference in San Diego, CA. The tutorial will be presented by Dr. James Hoying, Chief Scientist at Advanced Solutions, and Dr. Oksana Sirenko, Senior Scientist at Molecular Devices, on Monday, February 27, 2023, from 12:00 PM to 1:00 PM PST in Room 1B of the San Diego Convention Center. Tissue organoids and other 3D biological models have revolutionized biomedical research, particularly in the fields of drug and target discovery. However, deploying these models quickly and effectively requires turnkey workflow solutions that align automation with biology. This tutorial will describe an automated workflow for forming, bioprinting, culturing, transferring, assaying, and analyzing tissue organoid models using the BioAssemblyBot® 400 bioprinter and ImageXpress® Confocal HT.ai High-Content Imaging System. The session will also explore different tissue models, including patient-derived cancer organoids (PDOs), and discuss their use with various automated workflows. “We are excited to partner with Molecular Devices to present this tutorial at SLAS 2023,” said Dr. James Hoying, Chief Scientist at Advanced Solutions. “As tissue organoid modeling becomes increasingly important in biomedical research, it is critical that scientists have access to turnkey workflow solutions that can deploy these models quickly and accurately. This tutorial will provide a valuable overview of the latest automated workflow solutions for tissue organoid modeling, and we look forward to sharing our expertise with the SLAS community.” To attend this tutorial, please register for the SLAS 2023 Conference and visit Room 1B of the San Diego Convention Center on Monday, February 27, 2023, from 12:00 PM to 1:00 PM PST. For more information about the tutorial, please contact Advanced Solutions or Molecular Devices. About Advanced Solutions Advanced Solutions is a leader in 3D biotechnology, providing a range of solutions for tissue engineering, regenerative medicine, and drug discovery. The company’s BioAssemblyBot® platform is a fully automated bioprinting system that enables researchers to create complex solutions for a range of applications. For more information, please visit www.advancedsolutions.com. About Molecular Devices Molecular Devices is a leading provider of high-performance bioanalytical measurement solutions for life science research, pharmaceutical, and biotherapeutic development. The company’s solutions enable scientists to explore life at the cellular level and improve human health. For more information, please visit www.advancedsolutions.com/molecular-devices.

- Innovation Takes Center Stage: Advanced Solutions Life Sciences at SLAS 2023

The field of life sciences is advancing at a breakneck pace, and innovation is the driving force behind it all. At the forefront of this effort is Advanced Solutions Life Sciences (ASLS), a company dedicated to the discovery, design, and development of integrated software, hardware, and biological solutions. With its focus on integrating engineering and biology, ASLS is pushing the boundaries of what is possible in biomedical and biotechnology. What better platform for ASLS to showcase its cutting-edge technology than the Society for Laboratory Automation and Screening (SLAS) 2023 conference. The conference is a gathering of the brightest minds in the field of laboratory automation, bringing together academic, industry, and government researchers, as well as developers and providers of technology and tools. SLAS provides a unique opportunity for ASLS to demonstrate its patented BioAssemblyBot 3D Biofabrication Technology Platforms, TSIM Software, and VIPM. At the heart of ASLS's technology is the BioAssemblyBot, a highly sophisticated and agile robotic platform designed to revolutionize the world of biofabrication. With its ability to assemble biological structures with speed, precision, and cost-effectiveness, the BioAssemblyBot is set to shape the future of personalized medicine, cancer research, high-throughput assays, and regenerative therapeutics. ASLS's technology is already being used by some of the world's top global healthcare brands, and its products are UL cGMP certified, ensuring safety and quality. Visitors to the ASLS booth (#604 in the exhibition) at SLAS 2023 will have the chance to see the BioAssemblyBot in action and learn about the company's latest advancements in the field of biofabrication. In addition to showcasing its technology, ASLS will also be represented by Dr. Jay Hoying, the Chief Scientist of Advanced Solutions Life Sciences (ASLS). Dr. Hoying will be presenting on the topic of Automation of Complex Organoid Culture and Assay Workflows. This presentation is a rare opportunity for attendees to gain insights into the innovative work being done by ASLS in the field of biofabrication. SLAS 2023 San Diego, CA, USA February 25 - March 1, 2023 Advanced Solutions Life Sciences Exhibition Exhibition Hall (Booth #604) Sunday, February 26 from 4 PM to 7 PM Monday, February 27 from 10 AM to 6 PM Tuesday, February 28 from 10 AM to 6 PM Dr. Jay Hoying Presentation Poster Theater (#555 in Exhibition) Tuesday, February 28 from 1:40 PM - 1:50 PM

- BioAssemblyBot® Hand for Single Cell Printing A New Innovation from Advanced Solutions Life Sciences

Advanced Solutions introduces the Single Cell Dispense BAB Hand. Paired with BioApps(TM), the Single Cell Dispense BAB Hand enables a workflow that improves the efficiency and accuracy of single cell analysis. The Single Cell Dispense BAB Hand works on all BAB Models, including the BAB500, BAB400, and BAB200. One of the key benefits of the solution is the dual modality single cell assessment. Using both impedance and AI computer vision technology, our platform provides a more comprehensive view of individual cells and their behavior. This enables researchers to gain a deeper understanding of cellular responses and make more informed decisions. In addition to single cell isolation, the platform incorporates a range of automated workflows to streamline the research process. This includes monitoring and tracking each single cell isolation, incubation of the well plates before and after single cell dispensing, culturing the isolated single cells (including automated media change and imaging for cell health), and measuring protein production. By automating these processes, the platform reduces the risk of human error and saves time, allowing researchers to focus on data analysis and interpretation. It also enables researchers to process larger sample sizes, increasing the statistical power of their experiments. Watch the full workflow: Overall, the BAB Hand | Single Cell Dispense solution offers a comprehensive and efficient way to analyze individual cells, with a range of automated workflows to streamline the research process. With its dual modality single cell assessment, the platform provides a more comprehensive view of individual cells and their behavior, enabling researchers to make more informed decisions and gain deeper insights. Learn More about BAB Hands Learn More about BioApps

- Brown University | DOD Grant Automated Tissue Manufacturing with the BioAssemblyBot®

Brown University through a grant by the Department of Defense (DOD) has developed a novel automated tissue manufacturing process using Advanced Solutions' BioAssemblyBot® (BAB). BAB uses computer vision and artificial intelligence (AI) to autonomously assemble tissue components, such as rings or sheets, into more advanced structures, such as tubes or laminates, as part of the tissue manufacturing process. The video below showcases the Tissue Gripper BAB Hand stacking connective tissue rings that progresses, following fusion of the rings during culturing, to form the living precursor of a trachea. One of the key advantages of BAB is her ability to handle delicate tissue components with precision and consistency. The system uses computer vision to identify and track tissue components, allowing her to grip and transfer them with high accuracy. This is particularly important for fragile tissue components, which are difficult to handle manually without damaging them. Another advantage of BAB is her ability to perform tissue assembly tasks autonomously, without the need for human intervention. This not only reduces the risk of errors and contamination but also allows for the system to operate continuously, significantly increasing the efficiency and throughput of tissue manufacturing processes.

- Unraveling the Complex Interactions Between Gliomas and Blood Vessels

Gliomas are a type of brain tumor known for their ability to evade treatment. One of the ways they do this is through their unique interactions with blood vessels. Not only do they promote the growth of new blood vessels (angiogenesis), but they also hijack existing vessels (vessel co-option) and create their own vessels (vascular mimicry). These mechanisms allow the tumor to spread and make it harder for anti-cancer treatments to reach the tumor cells. Researchers at Advanced Solutions have developed a 3D in vitro model that mimics the human vascularized glioma tumor microenvironment. This model allows them to study the dynamics between glioma cells and blood vessels in a more realistic setting. In addition to the blood vessels, the model also includes macrophages, which are cells that play a critical role in the immune response. The study found that, consistent with observations in vivo, glioma cells stimulate angiogenesis. When treated with an anti-angiogenesis agent, the glioma cells physically interact with the angiogenic bed, and alter the inflammatory condition of the tissue environment. These findings suggest that disrupting the interactions between glioma cells and blood vessels could be a promising therapeutic target for treating gliomas. It is important to note that gliomas have the ability to initially respond to anti-angiogenesis therapy, but eventually escape through poorly defined, vascular-related mechanisms. This highlights the complexity of gliomas and the need for further research in this area. The Angiomics® 3D in vitro Glioma model provides an innovative approach to study these interactions and could lead to new treatments for gliomas. To learn more about this study, please refer to the full application note:

- Bringing Organoids to Life: Vascularization

Advanced Solutions Life Sciences is excited to reveal that its manuscript, "Vascularizing Tissue Organoids," has been published in a special edition of Regenerative Medicine in Bioengineering. The manuscript highlights ASLS’ cutting-edge Angiomics® technology and its various uses to the scientific community. Tissue organoids, also known as "mini organs," possess vast potential as tools for various applications, such as disease modeling, drug screening, and tissue engineering. To effectively imitate the native tissue environment, it is essential to integrate a microvasculature with the parenchyma and stroma. This is where Angiomics® technology comes into play, as it enables the creation of functional microvasculature within tissue organoids, providing a means to physiologically perfuse the organoids and contribute to the cellular dynamics of the tissue model through the cells of the perivascular niche. In the manuscript, the state of the art in this field is reviewed, and various strategies for vascularizing tissue organoids are discussed. The significance of perfusion in tissue organoids and how it contributes to the cellular dynamics of the tissue model is highlighted. Additionally, the importance of using human cells to create tissue organoids is discussed, as it provides a significant advantage over in vivo animal models, which are often not representative of cellular and disease behavior in humans. The advantages of using organoids over other in vitro systems and animal models are also discussed, such as their small size, which limits regions of necrosis that are often present in thicker tissue models, and the potential to be free from synthetic materials, containing only cells and their secreted matrix. Angiomics® technology allows for the creation of organoids that better approximate the in vivo tissue space than 2D cell cultures and mimic native tissue behavior and function with a high level of relevance. The company takes pride in being at the forefront of this exciting and rapidly advancing field and having its Angiomics® technology recognized by the scientific community. It looks forward to continuing its research and development in this field and creating new and innovative solutions for various applications in regenerative medicine and bioengineering. The authors of the manuscript are Hannah A. Strobel, Sarah M. Moss, and James B. Hoying, with James B. Hoying as the corresponding author. They are available to answer any questions regarding their technology and research at jhoying@advancedsolutions.com. View published manuscript: Web Version PDF Version

- Molecular Devices and Advanced Solutions collaborate to develop 3D Biology Automation Technologies

Turnkey platform integrates flexible robotic automation with high-content imaging of complex 3D cellular models, enabling high-volume organoid screening SAN JOSE, Calif., Jan. 4, 2023 – Molecular Devices, LLC., a leading provider of high-performance life science solutions, today entered into a partnership with Advanced Solutions Life Sciences, LLC (Advanced Solutions), a biofabrication company developing robotic platforms used to build biological structures. Under this partnership, Molecular Devices will commercialize the BioAssemblyBot® 400 (BAB 400) for Drug Discovery. Jointly developed by experts from both companies, the BAB 400 for Drug Discovery includes specific enhancements to Advanced Solutions’ existing bioprinting platform that helps life scientists overcome the challenges of reproducing consistent, complex organoid models at scale for drug development. Out-of-the-box integration of the BAB 400 with Molecular Devices’ ImageXpress® Cellular Imaging Systems enables turnkey automation of cell health monitoring and end-point assays. “Researchers are looking for a better way to develop and screen organoids when manual processes and manual technologies produce mixed results, wasting time and resources,” said Susan Murphy, President of Molecular Devices. “Partnering with innovators like Advanced Solutions addresses these pain points for our customers. The ImageXpress cellular imaging systems and BAB 400 deliver an automated, turnkey platform that improves the quality and viability of 3D cell cultures at higher throughput.” 3D cell models like self-organized organoids can speed the drug discovery process and reduce clinical trial failure rates due to their more human, biologically relevant structure. However, they can grow to be highly variable depending on the technology, workflows, and expertise in place, derailing reliability of endpoint assays. In a fully automated enclosure, BAB 400’s six-axis robotic arm uses a wide range of interchangeable BAB hands to systematically reproduce organoids, while the ImageXpress Confocal HT.ai system informs the modeling and screening process with high-content cellular imaging information for increased precision “Pairing the flexible yet controlled nature of BAB 400 with the image quality and speed of the ImageXpress automates high-content, 3D model research in a uniquely integrated and efficient process,” said Michael Golway, President & CEO of Advanced Solutions. “Together, we’re enabling users to quickly design, develop, and image complex organoids like never before. This is expected to improve efficacy and toxicity results, setting more novel therapeutics up for success.” Learn more about the collaboration here, or watch this on-demand webinar covering how ImageXpress Cellular Imaging Systems integrate with BAB 400 to advance 3D biology. This solution is available now to customers in Europe and North America. About Molecular Devices, LLC. Molecular Devices is one of the world's leading providers of high-performance bioanalytical measurement systems, software and consumables for life science research, pharmaceutical and biotherapeutic development. Included within a broad product portfolio are platforms for high-throughput screening, genomic and cellular analysis, colony selection and microplate detection. These leading-edge products enable scientists to improve productivity and effectiveness, ultimately accelerating research and the discovery of new therapeutics. Molecular Devices is committed to the continual development of innovative solutions for life science applications. The company is headquartered in Silicon Valley, California with offices around the globe. Visit Molecular Devices at www.moleculardevices.com. About Advanced Solutions Life Sciences, LLC Advanced Solutions Life Sciences, LLC (Advanced Solutions) is dedicated to the discovery, design, and development of integrated software and hardware solutions for life sciences, biotechnology, biopharma, and biomedical fields. Advanced Solutions is based in Louisville, KY, USA. Visit Advanced Solutions at www.advancedsolutions.com.

- Tumor Spheroid Workflows: Robot vs. Human

Organoids and spheroids are proving to be useful tools in drug target discovery and screening. The ability to scale up organoid production, culturing, and assaying is important in their widespread utility. Automation is key not only for increasing throughput, but also improving consistency and reducing the risk of human error during fabrication and use. We have previously demonstrated that, with the robotic BioAssembly™ Platform, adherent cells can be automatically passaged, cell suspensions can be dispensed into multiple well plates, and advanced 3D tissue models can be automatically fabricated, cultured, and assayed [1]. Here, we further demonstrate an automated tumor spheroid workflow with the Platform. The workflow consists of forming domes of Matrigel® containing tumor spheroids into wells of a 96 well plate; incubating in an integrated, modular incubator (BioStorageBot™); performing daily culture medium changes; and performing daily imaging via an automated interface with the Molecular Devices ImageXpress® Confocal HT.ai High-Content Imaging System. In the analysis, we compared spheroid morphology in cultures managed by the automated system to those managed by expert, standard manual practices. The BioAssembly™ Automation Platform The BioAssembly™ Platform (Figure 1) consists of BioAssemblyBot® 400 (BAB400) by Advanced Solutions, containing a 6-axis robotic arm capable of utilizing a wide range of interchangeable bioprinting, fluid dispensing, material movement, and tissue fabrication tools. Additionally, our modular BioStorageBot™ incubator and the ImageXpress® Confocal HT.ai High-Content Imager from Molecular Devices were integrated to complete the manufacturing Platform for this application. For this specific spheroid workflow, the Platform employed a BioAssemblyBot Hand™ (BAB Hand™) | Pipette, a BAB Hand™ | Pick & Place, and modular tube, pipette tip, cooling, and pipetting stations. All these components and the operational tasks to complete the workflow, including automated communication between the different instruments, are controlled by our user-friendly BioApps™ software, a software platform that connects, controls, and instructs the Platform to perform each step in a workflow. For this automated workflow (Figure 2), tumor spheroids were pre-formed manually by plating HCT-116 colorectal cancer cells (ATCC) into a non-adherent v-bottom plate at a concentration of 2,000 cells per well. After 24 hours, spheroids were suspended in 80% Matrigel® (a tumor cell-derived extracellular matrix frequently used to support spheroid cultures by providing a 3D environment and biological cues). 96 spheroids per 250 µl of cold Matrigel® was suspended in a sterile tube and placed within the cooling station within the Platform. Using the BAB Hand™ | Pipette, BAB400 aspirated from the chilled tube and then dispensed 5 µl of the spheroid/Matrigel suspension into the center of wells of a 96 well plate to form discernable domes on the bottom of each well. Only the central wells of the plate were used to avoid known edge effects of the outer wells (the outer wells were filled with buffer). Successful operations consisted of forming discernable domes that had not spread out into a thin disc on the well bottom (Figure 3). From this, 81.25% of wells contained discernable domes when dispensed by BAB400, compared to 72.0% when manually performed by an experienced scientist. After dispensing, a 10-minute wait period allowed the Matrigel® domes to gel before 50 µl of culture medium was added to each well followed by transfer to the BioStorageBot™ for culturing. BAB400 dispensed domes and added medium in 10’ 40” as compared to 15’ for the same number of domes when performed manually. Each day, as managed by the tumor-spheroid BioApp™, the BioAssembly™ Platform automatically performed culture medium exchanges and took transmitted light image acquisitions via the ImageXpress® Confocal HT.ai High-Content Imager (Figure 4). For medium exchanges, the plate is transferred to a modular tilt stage within the Platform that holds the well plate at an angle, analogous to someone holding the plate at a tilt when manually pipetting, allowing for more complete culture medium removal from each well without disturbing the Matrigel dome in the center. Workflow Outcomes From the daily images, the average size of individual spheroids was determined to be approximately half the diameter of those seeded manually as compared to those plated by BAB400 (the day 0 values in Figure 5). It was also noted that an average of 6.2 ± 2.8 spheroids were present in each dome formed manually in contrast to 2.0 ± 1.2 spheroids per dome formed by BAB400, the expected number based on seeding density. Combined, this suggests that the spheroids were fragmented by manual operations, perhaps via inconsistent pipetting rates, but not by the BioAssembly™ Platform. Over time, spheroids in both groups steadily increased their overall diameter (Figure 5). Calculation of spheroid growth rates indicated that individual spheroids increased in size at similar rates for both workflows (Figure 6). To assess organoid viability, ATP production (CellTiter Glo) was measured in spheroids cultured for three days by either the automation system or an experienced user. A viability index was calculated from luminesce values for each well, which were normalized to both spheroid number per well and average spheroid size (diameter) within that well (Figure 7). While there was an apparent higher viability index for the spheroids managed automatically as compared to those managed manually, this difference was not statistically significant. Summary and Discussion Here, we demonstrate an automated workflow in which cultures of colorectal cancer spheroids are established, maintained, and imaged autonomously via the BioAssembly™ Platform. The workflow entails all requisite operations, including the formation of Matrigel® domes housing the spheroids and interfacing with peripheral instruments (a BioStorageBot™ incubator and an ImageXpress® confocal scanner by Molecular Devices in this specific use case). Importantly, spheroid domes were not damaged during the workflow, including with daily media changes, resulting in consistently obtaining expected spheroid sizes and numbers per well. At the heart of the automation Platform is the BioAssemblyBot® 400, a 6-axis robotic arm used routinely in high precision manufacturing, housed within a framework uniquely suited for the fabrication, manipulation, and manufacturing of living systems, including spheroid/organoid and advanced 3D tissue models. Via a universal interface, the arm can utilize a wide spectrum of end effector tools (BAB Hands™), to perform varied tasks and operations, depending on the application. This functional flexibility, managed by the user via an intuitive software interface called BioApps™, affords the user considerable freedom in performing automated or semi-automated workflows, regardless of complexity. While this current application involved plate management (to multiple operational locations/stations) and precise pipetting, other applications have included 3D bioprinting, cell patterning, and fugitive molding, for example. The combined tasks leading to a prepared plate of spheroid domes including dispensing domes, gelation (10’ wait), dispensing media to domes, dispensing buffer to empty outer wells, and transfer to the BioStorageBot™ incubator took 26 min. 46 sec. The daily tasks of moving the plate of domes to and from the BioStorageBot™ for media exchanges and moving to and from the ImageXpress® scanner took 13 min. 40 sec. (not including scan time) for a total of 40 min 26 sec. When performed manually, this entire workflow took 41 min 24 sec (29 min + 12 min 24 sec). In addition to the time savings afforded by the automation, spheroids were not damaged, the expected number and size of spheroids per dome was attained, and there was improved consistency in dome formation. While we focused on spheroid size and number during routine culturing (i.e. without treatments), more advanced assays and assay readouts, such as the high content analysis following drug treatments, are possible with the BioAssemblyBot® 400 autonomously working in combination with the ImageXpress® Confocal HT.ai High-Content Imaging System from Molecular Devices. Furthermore, while a single plate was worked up for this study, the movement and material transfer capabilities of the robotic arm are readily amenable to conveyor and stacker solutions for continuous spheroid-related operations involving multiple plates thereby increasing throughput. References Moss, S.M., et al., Point-of-use, automated fabrication of a 3D human liver model supplemented with human adipose microvessels. SLAS Discov, 2022. Molecular Devices and ImageXpress are trademarks of Molecular Devices, LLC. Matrigel is a trademark of Corning, Inc. BioAssembly, BioStorageBot, BioAssemblyBot, BioAssemblyBot Hands, and BioApps are trademarks of Advanced Solutions, Inc. or its subsidiaries. Download Full Application Note:

- Building an NAFLD/NASH High-Throughput Amenable Human Liver Tissue Model

NAFLD/NASH Nonalcoholic fatty liver disease (NAFLD) and its aggressive form non-alcoholic steatohepatitis (NASH) occurs in the liver often in association with obesity, diabetes, metabolic syndrome [1, 2]. With the increased prevalence of these diseases in developed countries, NASH is the most common cause of most chronic liver disease in these areas. While a significant number of candidate pharmaceuticals are entering clinical development aimed at treating NAFLD/NASH, these pharmaceuticals were developed using rodent models and disease pathways/drug treatment has been shown to differ between human and rodent species. As such, more accurate models that recapitulate the human disease progression and pathways are needed [2-4]. NAFLD first manifests as fat accumulation within the hepatocytes of liver tissue, termed steatosis. This phase of liver disease is generally thought to be clinically harmless to the patient. However, many patients will experience progression of NAFLD to a NASH phenotype without dietary/lifestyle changes. NASH also involves accumulation of fats/lipids within the tissue but is accompanied by inflammation and fibrosis of the liver tissue microenvironment. Left untreated, this NASH phenotype typically progresses to liver cirrhosis and liver cancer [5]. MVP™-Liver: Advanced 3D Human Liver Tissue Model In previous work, we demonstrated the fabrication and characterization of a 3D thick (~1 cm) human liver tissue model compatible with standard multi-well plate formats that is fully automatable [6]. The high cell-dense liver tissue contains primary hepatocytes; non-parenchymal cells; and human, adipose-derived, microvessel fragments (Angiomics® haMVs) as a vascular source. The presence of the haMVs, which are comprised of multiple cell types normally residing in and on the microvessel wall, improves liver tissue function in the model over 14 days of culture, including increased drug transporter expression, P450 responsiveness, and increased non-parenchymal cell presence [6]. Importantly, the tissue is structured such that, despite the relative thickness, all cells are within 300 mm of a surface available for diffusion, regardless of the plate format used in the application. Here we use the same tissue modeling approach to fabricate this high cell-dense, 3D human liver tissue in a high throughput compatible format (standard 384 well plate) and explored its utility as a model for NAFLD/NASH. In this application, a single column of liver tissue was formed around a central space producing a cylinder approximately 0.6 cm tall within a single well (Figure 1A). The lumen provides good surface area for nutrient and gas exchange between the tissue space and the medium. Over the 14 days of culture examined, the tissue height and structure, including the central lumen persisted. In this application, the fabricated tissues consisted of a mix of 60 million primary hepatocytes (PH) per ml, 6 million non-parenchymal cells (NPCs) per ml (a 10:1 PH to NPC ratio), and 200K haMVs/ml. To begin exploring the utility of the model for NAFLD/NASH, liver tissues were exposed to a high fat medium (HFM) comprised of a base medium supplemented with glucose (25mM), palmitic acid (45μM), and sodium oleate (65μM). Additionally, dynamic tissue responses were explored by adding TGFβ1 (10ng/ml) alone or in combination with an ALK5 inhibitor (ALK5i; 5μM) to the high fat media supplements, where media was exchanged daily throughout the culture period. Findings were then compared to the appropriate vehicle control groups. After the experiment, tissues were fixed, end bloc stained with BODIPY, and imaged to measure lipid uptake, then processed for histology. Histologic sections and media supernatants were used to measure matrix deposition, urea, and inflammatory cytokine expression. Here, we observed increased lipid accumulation in hepatocytes and increased human collagen type I deposition of the liver tissues cultured in high fat medium, the two hallmarks of the disease. Additionally, we observed dynamic response of the NASH tissue to TGFβ1, which was abrogated by ALK5i, a TGFβ1 signaling inhibitor. Lipid Accumulation To induce a NAFLD/NASH phenotype, we supplemented the hepatocyte base media with glucose, sodium oleate, and palmitic acid to simulate dietary conditions most often associated with NAFLD/NASH. Furthermore, it has been shown by others to be an effective media to induce the relevant phenotype in 2D and 3D monocultures [7]. In both the high fat media (HFM) and vehicle control groups, urea production in the liver tissues dropped after the first day, likely reflecting cell dysfunction secondary to primary cell thawing and some energetic constraints (Figure 1B) [6]. However, no significant difference was observed in urea production between the treatment groups (Figure 1B). While urea cycle dysfunction can occur in NASH, it is not a typical hallmark of the disease and is often prevalent in only later manifestations of the disease [8]. Similarly, bile acid production was not significantly different between treatment groups (Figure 1C). While increased plasma bile acid levels are associated with NAFLD, it appears to occur in patients with insulin resistance co-morbidity [9], a situation likely not present in our liver tissues. To visualize accumulated lipids, tissues were en bloc stained with BODIPY and imaged via confocal microscopy. As expected, hepatocyte lipid accumulation was significantly increased in HFM-treated groups (Figure 1D), compared to the control group. This is an exciting result as it demonstrates the uptake of fatty acids by the hepatocytes, which is a clinical hallmark of NAFLD. Tissue Fibrosis Progression from an NAFLD phenotype towards a NASH phenotype is marked by inflammation and fibrosis within the tissue. Immunostaining for human collagen type I, an extracellular matrix (ECM) protein commonly associated with liver fibrosis, in histology sections revealed a significant increase in collagen I deposition in liver tissues of the HFM group as compared to control tissues (Figure 2A). In contrast, the deposition of collagen type III, another ECM protein associated with fibrosis, was not found to be different (Figure 2B). Interestingly, while the numbers of a-actin positive and CD45-positive cells tended to be higher in the HFM groups, a concomitant marker with fibrosis, no statistically significant difference was found (Figures 2C & 2D). Additionally, neither TNFα nor IL-6, the two major inflammatory cytokines associated with NASH, were detected in tissue supernatants via ELISA (data not shown). Therefore, the presence of increased collagen I deposition in the absence of inflammatory cytokine production suggests that fibrosis is initiated in the liver model with HFM treatment in the absence of an inflamed tissue environment. NASH promotion: TGFb1 treatment Given that tissue inflammation is associated with NASH, we included TGFβ1 alone or in combination with ALK5i in the high fat media supplements as treatment groups to assess the dynamic response of the tissue to TGFβ1, an inflammatory mediator. Neither the presence of TGFβ1 alone nor in combination with ALK5i had a significant effect on urea or bile acid production (Figures 3A & 3B). Interestingly, TGFβ1 promoted increased lipid accumulation by hepatocytes as compared to the vehicle control group, an increase of which was abrogated by ALK5i (Figures 3C - 3F). Interestingly, given the generalized role of TGFβ1 in tissue inflammation, there was no evidence of additional fibrosis (collagen I or III deposition), inflammatory cytokine expression (IL-1 and IL-6), or changes in NPC cell populations in the presence of TGFβ1 with or without ALK5i (Figures 4A - 4H) above that induced by HFM + vehicle, suggesting that in our model, treatment with TGFβ1 alone is insufficient to induce a NASH phenotype. Additionally, we observed vehicle effects when comparing values for the HFM + vehicle (EtOH + citric acid) in this set of TGFβ1-related experiments to the HFM + vehicle (EtOH) in the previous set of experiments, suggesting that the EtOH + citric acid combination had a suppressive effect on lipid accumulation (see Figures 1 vs 3). Summary and Discussion In this pilot study, we demonstrate the reconfiguration of our 3D thick, human liver tissue model into a standard 384 well format towards improving assay throughput. Indeed, we were able to fabricate, culture and assay the high cell-dense liver tissues (60 million hepatocytes/ml of starting tissue) over a 2-week period similar to what we have reported earlier for larger sized tissue formats [6]. While not explored here, we have previously demonstrated that this human vascularized liver tissue model is amenable to laboratory automation using standard well-plate formats [6], making this 384 well plate format an enticing option for high throughput screening. Furthermore, we demonstrate that the small tissue volumes, which make the model more economical given the high cell density, continue to provide sufficient biology for assay endpoints. Related to this, we demonstrate clear differences in liver tissue responses towards NAFLD- and NASH-like in vitro challenges related to lipid accumulation and fibrosis. Other indicators such as non-parenchymal cell activation and inflammatory cytokine production did not show a significant difference, although there were trends in these assay endpoints consistent with an NAFLD/NASH phenotype, particularly with the TGFβ1 treatment consistent with a possible NAFLD/NASH-like response. 3D liver cell co-cultures (hepatocytes plus other liver tissue cell types) have been repeatably shown to be more functional and representative of the in vivo microenvironment, as signaling between NPC cells, vascular cells, and hepatocytes is important in healthy and pathological dynamics. Interestingly, in contrast to 2D mono- and co-cultures and 3D monocultures which exhibit simple markers of NASH due to elevated oleic and palmitic fatty acid levels [13], 3D liver co-culture models required an additional insult, such as with cyclosporine [10], methotrexate [11], or fluid flow-related cues [12] to induce the NASH phenotype. As others have suggested, a more complex cellular environment in a tissue model likely plays a modulating role in tissue disease progression, requiring a more aggressive and/or chronic insult to progress towards disease in vitro. This may explain why the inclusion of TGFβ1 in our studies, intended to provide a more natural co-stimulus with the HFM, did not push our model fully towards a frank NASH phenotype. Regardless, the early indicators of NAFLD/NASH in our 3D human liver tissue model, which has a more dynamic cellular environment configured in a throughput-friendly format, may prove useful in gaining more insight into the relevant disease processes, which existing in vitro models have not been able to fully address. References Kořínková, L., et al., Pathophysiology of NAFLD and NASH in Experimental Models: The Role of Food Intake Regulating Peptides. Front Endocrinol (Lausanne), 2020. 11: p. 597583. Ramos, M.J., et al., In vitro models for non-alcoholic fatty liver disease: Emerging platforms and their applications. iScience, 2022. 25(1): p. 103549. Ströbel, S., et al., A 3D primary human cell-based in vitro model of non-alcoholic steatohepatitis for efficacy testing of clinical drug candidates. Sci Rep, 2021. 11(1): p. 22765. Boeckmans, J., et al., Human-based systems: Mechanistic NASH modelling just around the corner? Pharmacol Res, 2018. 134: p. 257-267. Fernando, D.H., et al., Development and Progression of Non-Alcoholic Fatty Liver Disease: The Role of Advanced Glycation End Products. Int J Mol Sci, 2019. 20(20). Moss, S.M., et al., Point-of-use, automated fabrication of a 3D human liver model supplemented with human adipose microvessels. SLAS Discov, 2022. Müller, F.A. and S.J. Sturla, Human in vitro models of nonalcoholic fatty liver disease. Current Opinion in Toxicology, 2019. 16: p. 9-16. De Chiara, F., et al., Urea cycle dysregulation in non-alcoholic fatty liver disease. J Hepatol, 2018. 69(4): p. 905-915. Grzych, G., et al., NASH-related increases in plasma bile acid levels depend on insulin resistance. JHEP Rep, 2021. 3(2): p. 100222. Bell, C.C., et al., Characterization of primary human hepatocyte spheroids as a model system for drug-induced liver injury, liver function and disease. Sci Rep, 2016. 6: p. 25187. Leite, S.B., et al., Novel human hepatic organoid model enables testing of drug-induced liver fibrosis in vitro. Biomaterials, 2016. 78: p. 1-10. Feaver, R.E., et al., Development of an in vitro human liver system for interrogating nonalcoholic steatohepatitis. JCI Insight, 2016. 1(20): p. e90954. Green, C.J., et al., Studying non-alcoholic fatty liver disease: the ins and outs of in vivo, ex vivo and in vitro human models. Horm Mol Biol Clin Investig, 2018. 41(1). Strobel, H.A., T. Gerton, and J.B. Hoying, Vascularized adipocyte organoid model using isolated human microvessel fragments. Biofabrication, 2021. Angiomics Human Adipose Microvessels by Advanced Solutions are for RESEARCH USE ONLY and not for use in humans under any circumstances. Advanced Solutions Life Sciences, LLC. and Advanced Solutions, Inc. are not responsible or liable for how this product is used. The RESEARCH USE ONLY limitation supersedes any written, oral, or implied understanding between the parties. View Human Adipose Microvessels Safety Data here. Download Full Application Note:

- BAB Empowers Breast Cancer Survivors with New Prosthetics

October is Breast Cancer Awareness Month and BAB is empowering women with a new type of breast prosthetics through pioneering research by Dr. Liisa Kuhn at the University of Connecticut. Dr. Kuhn, Professor and Associate Head of Biomedical Engineering at UConn, leads the development of new, more natural looking, and comfortable breast forms. “I came up with the idea for a 3D printed breast prosthetic when a colleague at UConn Health was talking about how she had had cancer and she had received excellent care, but she was struggling and frustrated with the options out there for breast prosthetics” said Dr. Kuhn. This led to Dr. Kuhn finding new materials to create new prosthetics. WFSB covered the process of creating custom breast prosthetics on a segment of “Great Day Connecticut.” Dr. Kuhn uses medical imaging of a survivor’s chest to then create computer renderings. She and her team can then digitally model a reconstructed breast. Turning that model into a physical item requires the use of a BioAssemblyBot® 400 (#WeCallHerBAB) at the University of Connecticut. In a matter of hours, Dr. Kuhn can create breast forms that are precise to the survivor’s body. The forms are then inserted into a specially designed bra to give women a natural-looking chest and more importantly a sense of empowerment with improved self-confidence. “They gave me back a little of what I was before. They gave me back that little spark again” said Jan Figueroa, a breast cancer survivor. Courtesy: UConn Health

- BioAssemblyBot® Featured at ‘Life Itself’

BioAssemblyBot®, or BAB, as we call her, was featured at the Life Itself event in San Diego. Among the select few non-humans to be featured, BAB was onstage during a presentation on the future of on-demand human hearts for transplant presented by Organamet Bio CEO and research pioneer, Dr. Doris Taylor. Together with the Advanced Regenerative Manufacturing Institute (ARMI) and others, BAB and Advanced Solutions is establishing a new protocol for taking un-transplantable hearts, from donors, and turning them into new, living organs with the recipients’ own cells. Read full story on CNN: https://www.cnn.com/2022/06/01/health/ghost-heart-life-itself-wellness/index.html Watch Dr. Doris Taylor's full presentation: https://www.cnn.com/videos/health/2022/06/01/doris-taylor-life-itself-wellness.cnn About Life Itself Life Itself, in partnership with CNN, is a new in-person event set to celebrate extraordinary minds and ideas in health and medicine moderated by Dr. Sanjay Gupta. This trailblazing symposium featured world-renowned doctors, scientists, and public figures including Scott Kelly, Dr. Anthony Fauci, Chelsea Clinton, Norman Lear, Kimbal Musk, Adrianna Huffington, Rochelle Walensky, and more.

- BioAssemblyBot® to be Featured at ‘Life Itself’

BioAssemblyBot®, or BAB, as we call her, will be featured at Life Itself event in San Diego. Life Itself, in partnership with CNN, is a new in-person event set to celebrate extraordinary minds and ideas in health and medicine moderated by Dr. Sanjay Gupta. This trailblazing symposium features world-renowned doctors, scientists, and public figures including Scott Kelly, Dr. Anthony Fauci, Chelsea Clinton, Norman Lear, Kimbal Musk, Adrianna Huffington, Rochelle Walensky, and more. Among the select few non-humans to be featured, BAB will be onstage during a presentation on the future of on-demand human hearts for transplant presented by Organamet Bio CEO and research pioneer, Dr. Doris Taylor. Together with the Advanced Regenerative Manufacturing Institute (ARMI) and others, BAB and Advanced Solutions is establishing a new protocol for taking un-transplantable hearts, from donors, and turning them into new, living organs with the recipients’ own cells.

- BioAssemblyBot 500 is a Finalist for Product of the Year

Manchester, NH, USA – The BioAssemblyBot®500 has been named a finalist for Product of the Year by the New Hampshire Tech Alliance. The annual competition is one of New Hampshire’s largest business events according to event organizers. The BAB500, introduced earlier this year, is an industry unique six-axis robotic bioprinter that fully operates inside a Class II, Type-A biosafety cabinet. The BAB500 incorporates a unique combination of technologies to enable clinic-grade manufacturing of human tissue models for new drug discovery and research, and therapeutic tissues at the point-of-use. “Being in the running for Product of the Year is truly a distinguishing honor, especially among a crowded field of excellent innovations from our fellow finalists. We are so excited to share BAB500 and appreciate this opportunity,” said Dr. Jay Hoying, Partner and Chief Scientist of Advanced Solutions’ New Hampshire research facility. You’re invited to join in the voting process on October 28th, 2021, at 3:00pm eastern. Dr. Jay Hoying will be presenting the groundbreaking technology. Following his presentation and the presentations from our fellow finalists, you will have the opportunity to vote for BAB500. The audience results will be combined with the technical judges scores from the NH Tech Alliance to select the 2021 Product of the Year. Learn more and register for the event here: https://nhtechalliance.org/nhhtc-events/product-of-the-year/ About Advanced Solutions Life Sciences, LLC: Advanced Solutions Life Sciences, LLC (Advanced Solutions) is dedicated to the discovery, design, and development of integrated software and hardware solutions for the fields of science that involve living organisms, molecular biology, and biotechnology. Advanced Solutions research facility is located in Manchester, NH, USA and is headquartered in Louisville, KY, USA. About the Product of the Year Competition: Product of the Year (POY) is a competitive event which offers the local business community an opportunity to recognize the outstanding achievements of companies who develop innovative technology products in New Hampshire. As across the United States, New Hampshire has seen an increasingly competitive marketplace in the tech sector. POY is an interactive, fun, and incredibly invigorating night to see local companies pitch their latest and greatest technological products. About New Hampshire Tech Alliance: The NH Tech Alliance is a statewide technology association dedicated to supporting companies at every stage of growth and development – from startups to established leaders in the global economy. We are committed to nurturing a vibrant tech ecosystem in NH by building partnerships, enhancing knowledge and shaping public policy.

- Light-based Crosslinking Made Cell-friendly

Biomaterials used for fabricating 3D tissue constructs need to provide a permissive environment for cellular processes while also maintaining high levels of structure fidelity. It is common for materials that are biologically friendly to exhibit lower viscosity, rendering a lower structural fidelity. Therefore, there is a large collection of materials that contain chemical moieties for bulking up the material after the extrusion process that become activated with light. The BioAssemblyBot® family of bioprinters can be equipped with print heads that enable the light-based crosslinking of materials. The UV print heads (3D Syringe | UV and 3D Syringe | Hot + UV) for the BioAssemblyBot® platform provide on-tool light-based crosslinking that can be executed while a material is being extruded or conduct a cure path post-printing as per the user input parameters. This ring light-based technology is available at both 365nm and 405nm wavelengths and is rated at 300-watt cm2, with the ability to change values at 1mw increments. Options for extrusion include ambient or room-temperature based prints as well as heated extrusion, where the material can be heated up to 150C (see Figure 2). Bringing in this capability to a workflow is made seamless through automated tool calibration and the intuitive materials settings interface within the TSIM® software program. Altogether, these innovations enable higher success rates in the utilization of materials that require light-based crosslinking for fabricating 3D tissue constructs. You can learn more about the 3D Syringe | UV BioAssemblyTool here and the 3D Syringe | Hot + UV BioAssemblyTool here.

- BioAssemblyBot® 500: The Future of Curative Healthcare

FOR IMMEDIATE RELEASE ADVANCED SOLUTIONS ANNOUNCES THE BIOASSEMBLYBOT® 500, AN INDUSTRY FIRST SIX-AXIS BIOPRINTER IN A BIOSAFETY CABINET 8/31/2021 LOUISVILLE, KY, USA – Building on the BioAssembly™ revolution, Advanced Solutions announces the latest bioprinter in the BioAssemblyBot® technology platform. The BioAssemblyBot® 500, or BAB500 for short, is an industry unique six-axis robotic bioprinter that fully operates inside a Class II, Type-A biosafety cabinet. BAB500 builds upon the award winning BioAssemblyBot® 400 six-axis technology platform, incorporating a seamless integration with a rich library of BioAssemblyTools™, TSIM® and BioApps™ software. Leveraging over 75,000 engineering and scientific research and development hours, the BAB500 incorporates a unique combination of technologies to enable clinic-grade manufacturing of human tissue models for new drug discovery and research, and therapeutic tissues at the point-of-use. “These next generation tissue solutions will be custom manufactured as needed in a controlled setting without the very problematic challenges of shipping and storing living tissues. And the BioAssemblyBot® 500 will lead the on-demand curative healthcare market,” said Dr. Jay Hoying, Chief Scientist of Advanced Solutions. “The BioAssemblyBot® 500 represents the best of our innovation at Advanced Solutions and a culmination of over 10-years developing the BioAssembly™ Technology Platform. BAB500 is specifically designed for pharma and clinical applications. It will be used by leading scientist around the world to design personalized patient pharma treatments, unique to the patients body and DNA, and by surgeons to replace diseased or damaged tissues using the patients DNA as the raw material. The BioAssemblyBots® are getting smarter and smarter and are learning how to assemble biology in ways that creates functional and useful solutions for humans. The technology is now available to unleash a tidal wave of cures and healthcare solutions.” said Michael Golway, President & CEO of Advanced Solutions. Just like the other BioAssemblyBots® from Advanced Solutions, BAB500 features a universal adapter on the end of the robotic arm’s wrist allowing for bioprinting, pipetting, moving materials around, and more within the safety of the closed biosafety cabinet. Up to ten BioAssemblyTools™ can be used in a single run. And, just like the other BioAssemblyBots®, BAB500 is driven by powerful software suite including TSIM® and BioApps™. TSIM®, enables 3D design freedom, creating complex, biomimetic objects with point and click 3D CAD software. Additionally, with BAB500, users can complete complex assays and protocols using BioApps™. BioApps™ enable multi-step processes that can be done without human interaction. BioAssemblyBot® 500 will revolutionize tissue manufacturing and curative healthcare. You can learn more about BioAssemblyBot®500 at: advancedsolutions.com/bioassemblybot-500 About Advanced Solutions Life Sciences, LLC: Advanced Solutions Life Sciences, LLC (Advanced Solutions) is dedicated to the discovery, design, and development of integrated software and hardware solutions for the fields of science that involve living organisms, molecular biology, and biotechnology. Advanced Solutions is based in Louisville, KY, USA.

- A Conversation with Dr. Jay Hoying

Advanced Solutions Life Sciences is excited to launch a new Podcast Series on 3D Biology! The inaugural episode is with our own Chief Scientist, Dr. Jay Hoying, where he shares his insights on the inherent complexity of vascularizing 3D tissues. Download the accompanying slideshow here:

- Advanced Solutions is Hiring

Do you love 3D bioprinting and tissue fabrication? Do you accept new challenges head-on and with enthusiasm? You may be perfect for our growing team! Advanced Solutions Life Sciences, LLC is seeking applicants for two positions within our organization. Manufacturing Assembly and Quality Controller – Louisville, KY The Manufacturing Assembler and Quality Controller is a full-time position that supports the engineering team. They will ensure a successful customer experience by assisting the engineers in assembling BioAssemblyBots®, in order to insure timely delivery to customers. This position works closely with the engineering team to improve quality of assembly, testing, and calibration documentation. This position reports to engineering management. You can learn more about and apply for this position here. Tissue Fabrication Intern – Manchester, NH Advanced Solutions Life Sciences is seeking a full-time/part-time intern at our Manchester, NH location for Fall 2021 and/or Spring 2022. Our Manchester office leads a variety of projects focused on tissue engineering and tissue vascularization, using state of the art bioprinting systems. The position will involve assisting in product development, customer bioprinting projects, and laboratory maintenance. Tasks may include small bioprinting projects, product quality control, image analysis, developing product documentation, and basic laboratory maintenance. The ideal candidate will be working towards a bachelor’s or graduate degree in biology, biotechnology, biomedical engineering, or related fields. Interested applicants MUST be detail oriented, a quick learner, and capable of working independently as well as part of a team. Experience working with aseptic technique is preferred but not required. You can learn more about and apply for this position here. Advanced Solutions Life Sciences, LLC is a subsidiary of Advanced Solutions, Inc. (ASI). ASI is an equal opportunity employer. ASI will only employ those who are legally authorized to work in the United States. Any offer of employment is conditional upon the successful completion of a background investigation and drug screen. Software

- Large construct fabrication requirements? No problem!

The BioAssemblyBot® technology platform can automatically switch between different tools or print heads as required for different biofabrication tasks. At the end of the BioAssemblyBot® 400’s 6-axis robot arm, there is a universal adapter system that enables flexibility in the types of tools available for use in a wide variety of fabrication tasks. With that in-mind, one of the latest in tool innovations is the ability to accommodate the use of larger volume syringes or cartridges. The BioAssemblyBot® 400’s arm has the strength to pick up the payload required for these larger volumes, while also having the flexibility to enable the proper orientation required for the extrusion of materials from larger receptables. This innovation was born out of the need to fabricate large sized constructs without the requirement to change print heads or manually swap/load materials. Additionally, this type of tooling can also assist in fabrication strategies that require throughput while utilizing the same material. These BioAssemblyTools™ are designed for ambient based extrusion of materials that are syringe loadable. Current tool offerings include the ability to accommodate 100ml and 500ml syringe barrels and can be used with off-the-shelf consumables. You can learn more about the 3D Syringe | 100ml here and the 3D Syringe | 500ml here.

- Advanced Solutions Announces Strategic Partnerships

FOR IMMEDIATE RELEASE 7/20/2021 LOUISVILLE, KY, USA – Advanced Solutions today announced that it has entered into agreements with Vital Health Technologies, LLC (VHT) of Doha, Qatar and their sister company, H&D Medical Store and Equipment Trading, LLC (H&D Medical) of Dubai, UAE, leading medical and research technology solution providers in their markets, as regional business partners for the BioAssemblyBot® technology platform in Qatar and the UAE markets. "With VHT and H&D Medical as our business partners in the region it strengthens our commitment to bring a profound and positive platform to the brightest scientists and clinicians on the planet,” said Michael Golway, CEO and President of Advanced Solutions. “Working with the teams at VHT and H&D Medical has been great and we are excited for the opportunity to better serve the Qatar and UAE markets.” “The strategic partnership with Advanced Solutions is consistent with our mission to support our research & clinical customers across Qatar and UAE,” said Darious K.K., CEO of VHT and H&D Medical. “We firmly believe through this partnership we continue to deliver an advanced technology platform to help, support and improve the healthcare system and our valued customers vision towards achieving the best in industry.” VHT and H&D Medical will be the channel partners of Advanced Solutions’ BioAssemblyBot® technology platform in Qatar and the UAE. The patented and cGMP-certified platform is an intelligent agile robotic platform used to build and assemble biological structures. More than a 3D bioprinter, BioAssemblyBots® leverages over 60 years of industrial robotic innovation to bring speed, quality, high-precision and low-cost manufacturing to the task of building tissues and organs. The BioAssemblyBots® are uniquely qualified to meet scientists’ needs. BioAssemblyBot® 400 (BAB400) is the most advanced bioassembly platform, with a six-axis arm, BAB400 uses machine vision and artificial intelligence to bring science to life. The BioAssemblyBot® 200 (BAB200) is a four-axis bioprinter that takes three forms: biosafety cabinet ready, enclosed, and enclosed with HEPA filtration. The BABs have a common bond of enabling a teachable robot platform to automate 3D biology and build 3D human tissue models. Enabling this are BAB’s interchangeable hands. At the end of the robotic arm there is a universal connector that joins with a growing library of BioAssemblyTools™ that can inject cells, build 3D biology, move material around, and pipette at microprecision. With the agreement, VHT and H&D Medical’s valued medical research, key opinion leaders, and surgeons will have access to the same great support from the Advanced Solutions team. You can learn more about the BioAssemblyBot® 400 at advancedsolutions.com/bioassemblybot-400 and the BioAssemblyBot® 200 at advancedsolutions.com/bioassemblybot-200. About Advanced Solutions Life Sciences, LLC: Advanced Solutions Life Sciences, LLC (Advanced Solutions) is dedicated to the discovery, design, and development of integrated software and hardware solutions for the fields of science that involve living organisms, molecular biology, and biotechnology. Advanced Solutions is based in Louisville, KY, USA. About Vital Health Technologies, LLC: Vital Health Technologies, LLC (VHT) is a medical and research technology distribution company that delivers services and solutions to the healthcare and clinical research industry. VHT is based in Doha, Qatar. About H&D Medical Store and Equipment Trading, LLC: H&D Medical Store and Equipment Trading, LLC (H&D Medical) is a value-added equipment reseller that seeks to not just distribute healthcare technologies but to partner with customers to meet their needs. H&D Medical is based in Dubai, UAE.

- 3D Bioprinting Vasculatures

3D bioprinting vasculatures is perhaps the holy grail of the next industrial revolution in healthcare. Biofabrication and bioprinting of any viable three-dimensional tissue will not be successful unless the vascularization challenge has been solved. Many organizations and talents around the world are actively tackling this challenge, but where are we exactly? Hear the latest perspectives, updates, and revelations from a group of technical and industrial superstars. Advanced Solutions’ Chief Scientist, Dr. Jay Hoying, and Business Development Manager, Dr. Lehanna Sanders will be speaking at this webinar hosted by 3DHeals. Other speakers include Andrew Hudson, Jordan Miller, and Prafulla Chandra. WHAT: 3D Bioprinting Vasculatures WHEN: July 22, 2021 at 11:00am est WHERE: Virtual (Zoom) PRESENTED BY: 3DHeals Register to attend here: https://3dheals.com/3d-bioprinting-vasculatures

- Designing and Equipping 3D Bioprinting Facilities

In July’s Thought Leader piece for GEN, William Whitford and Dr. Lehanna Sanders, review the different considerations required for developing facilities centered around 3D bioprinting technologies. This review includes considerations to support an overall workflow for a variety of applications such as the requisite environmental classifications, bioprinting process support, as well as equipment selection. Click here to read the full article.

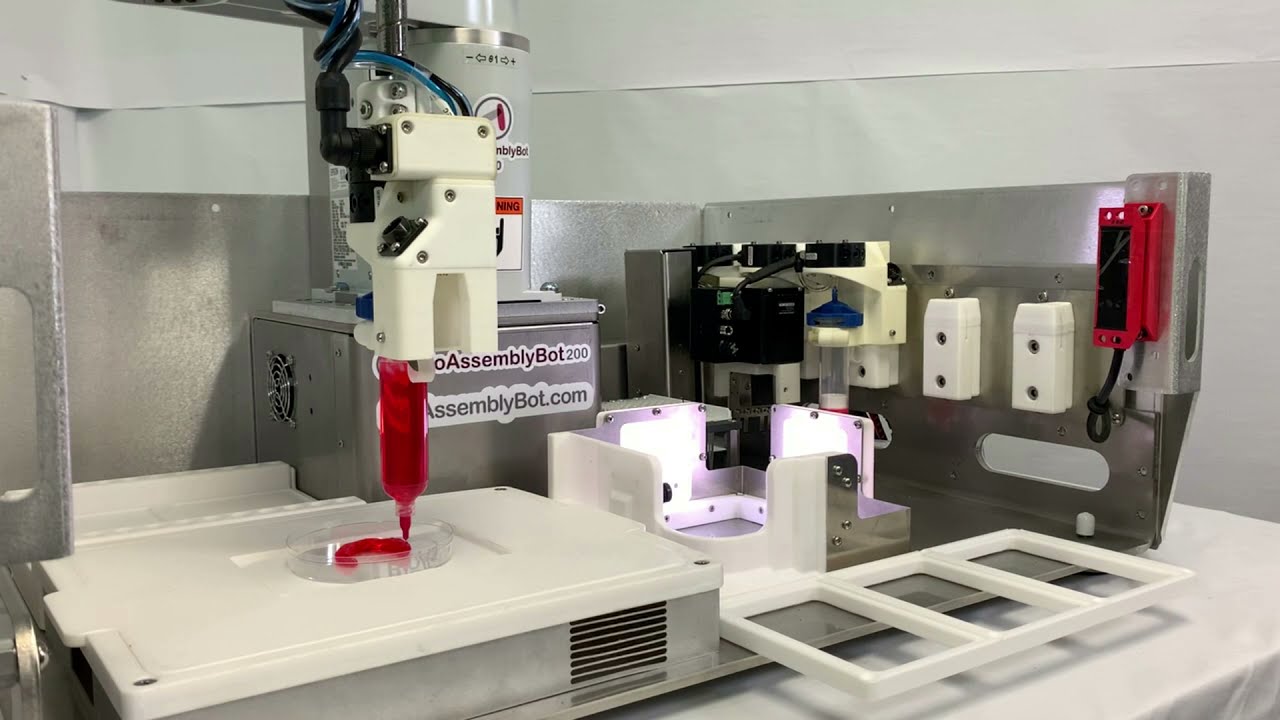

- Extraordinary Discoveries with BioAssemblyBot 200

Advanced Solutions Life Sciences utilizes the newest technologies in robotics, artificial intelligence, and vascular biology to enable clients to easily and repeatably build viable 3D human tissue models. BioAssemblyBot® 200, or BAB200 as we call her, is an all-in-one platform that takes you from the idea stage quickly to execution. BAB200 is a versatile and flexible system, available in different configurations, but sharing a common bond of enabling a teachable robot platform to automate 3D biology and build 3D tissue models. BioAssemblyBot® 200 combines four-axis robotics with three unique forms to meet your needs. Whether in its enclosed form on the benchtop, equipped with a HEPA filtration system, or in a biosafety cabinet, BAB200 is a powerhouse for 3D biology capability. One of the many features of BAB200 are her interchangeable hands. At the end of her wrist there is a universal connector that joins with a growing library of BioAssemblyTools™. Yes, a robotic hand for every task including plate transfer, pipetting microliter volumes of fluids, as well as a variety of extrusion methods to name a few. BAB200 even offers our clients the ability to build their own BioAssemblyTools™. Therefore, the BioAssemblyBot® 200 is more than a 3D bioprinter. With bays for up to five active BioAssemblyTools™, BAB200 offers flexibility in the bioprinting workflow to deliver a rich library of capabilities ensuring a return on investment that will supercharge research results. You can learn more about BAB200 at advancedsolutions.com/bioassemblybot-200.